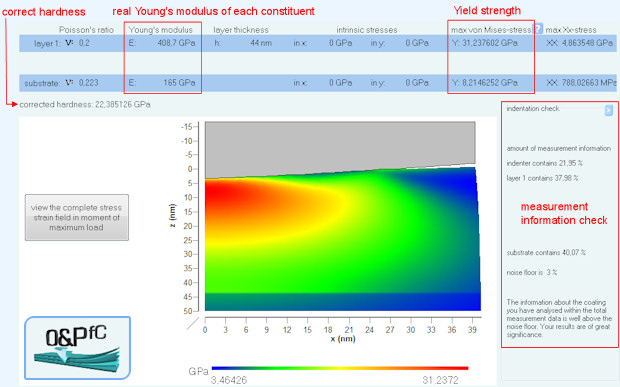

The OPfC® (Oliver & Pharr for Coatings) module enables you to mechanically characterize complex surfaces properly by fully automatic analysis of indentation measurements. Such a mechanical characterization requires calculation of generic material properties including the real Young’s modulus of each layer, the yield strength of each layer, and the Poisson’s ratio of each layer, which only OPfC® can evaluate for almost arbitrary structured materials. Particularly, its simple handling allows you to gain more information out of remaining or performed measurements within a few minutes only. Due to the automation of the procedure, you get not only the requested Young’s modulus in the twinkling of an eye, but also the complete evaluation (33 field variables likes von-Mises-stress, normal stresses etc.) of the elastic stress-strain field inside the sample.

Features

The features covered below are features of the model on which this product series is based. Therefore, they may differ from the capabilities of the individual editions as they are not all completely implemented in all editions.

Supported Material Structures

This software series allows you to analyze among others the following surface structures by evaluation of mechanical contact measurements:

- multi-layer coatings (up to 100 layers)

- thin films (theoretically down to 1 angstroem*)

- thick films (theoretically unlimited*)

- with intrinsic/thermal stresses and gradients of it (functional)

- laminate structures

- composites

- nano-particle-enhanced coatings (nanotubes, fullerenes, …)

- inclusions and defects not only within layers but also at interfaces

- superlattice

- homogeneous monolithic bulk materials (e.g. substrate only)

* Practically it depends on capabilities (e.g. the resolution and noise floor) of your measurement instrument.

Measurement Conditions

Among others, the following measurement conditions and measurement effects can be taken into account for the evaluation of mechanical surface measurements by this measurement analysis software series:

- multi-axial loads (normal, lateral, and rotating loads)

- actual indenter shape, hence also edges and asymmetry of indenter tips (e.g. required for Berkowich and Vickers tips)

- creep / sink-in: time-dependent material properties of viscous or visco-elastic materials (e.g. polymers)

- pile-up / residual stresses of ductile materials, plastic deformation, fractures/cracks of brittle materials

- temperature gradients / fields (e.g. necessary for high temperature measurements or tribology tests)

- weak interfaces / poor interface adhesion

Evaluable Contact Measurements

The OPfC® module enables you to analyze the following mechanical surface measurements:

- instrumented nano, micro, and macro indentation measurements and hardness tests, respectively

- multi-axial indentation measurements (with additional lateral or rotating loads)

- cyclic, dynamic, and multi-load indentations (e.g. Continuous Stiffness Measurement method of Agilent, Quasi Continuous Stiffness Measurement method of ASMEC, ESP of Fischer)

- high temperature indentations

- and many more

Mechanical Characterization

The most important aim of mechanical characterization is the evaluation of generic material properties, which are independent of measurement conditions (like material structure of the sample, maximum indentation depth etc.). Hence, it is necessary to take all these measurement conditions into account to evaluate such a measurement properly. That is why we have extended the classic Oliver & Pharr method for such conditions. This Oliver & Pharr method extended for layered materials (Oliver & Pharr for Coatings) enables you to calculate – among others – the following generic material properties:

- real Young’s modulus (elastic modulus) of each layer or substrate

- yield strength of each layer or substrate

- Poisson’s ratio of each layer or substrate

- intrinsic, thermal, or residual stresses of each layer or substrate

- layer thicknesses

- time-dependent elastic modulus of visco-elastic materials (e.g. foams, tissues, polymers)

- dynamic parameters like storage modulus E’ and loss modulus E”

Only these generic physical material properties can be reused in nearly any other surface structure (e.g. for surface optimization by means of modeling and simulation or for analysis of complex contact measurements like scratch tests) without being obliged to repeat the characterization.

The OPfC® allows one to determine the correct hardness, too. But be aware: Hardness is neither a physical nor a generic material property!

Result page of OPfC®, showing real Young’s moduli, yield strength, corrected hardness, and measurement information share of each constituent.

Connection to Measurement Equipment

The following measurement equipment manufacturers already provide a direct export interface to our software, which convert measurement data directly into our format:

- Helmut Fischer GmbH

- ASMEC GmbH – member of Zwick/Roell

- MicroMaterials Ltd.

- Anton Paar (formerly CSM Instruments)

Further manufacturers are still developing and will follow soon.

Tutorial Videos

Our student Julius demonstrates in the next videos how to use the OPfC® module.

Ask us for specific consulting

Mail: info@siomec.de